diy headboard wall – part 2 by andrea beckman

At last….I’ve finally completed my ‘headboard wall’! If you have not checked out my first post diy upholstered headboard – part 1, I started this project over two months ago and it has been on my ‘to-do’ list for about seven! None the less it’s finally complete and I’m happy to say it turned out […]

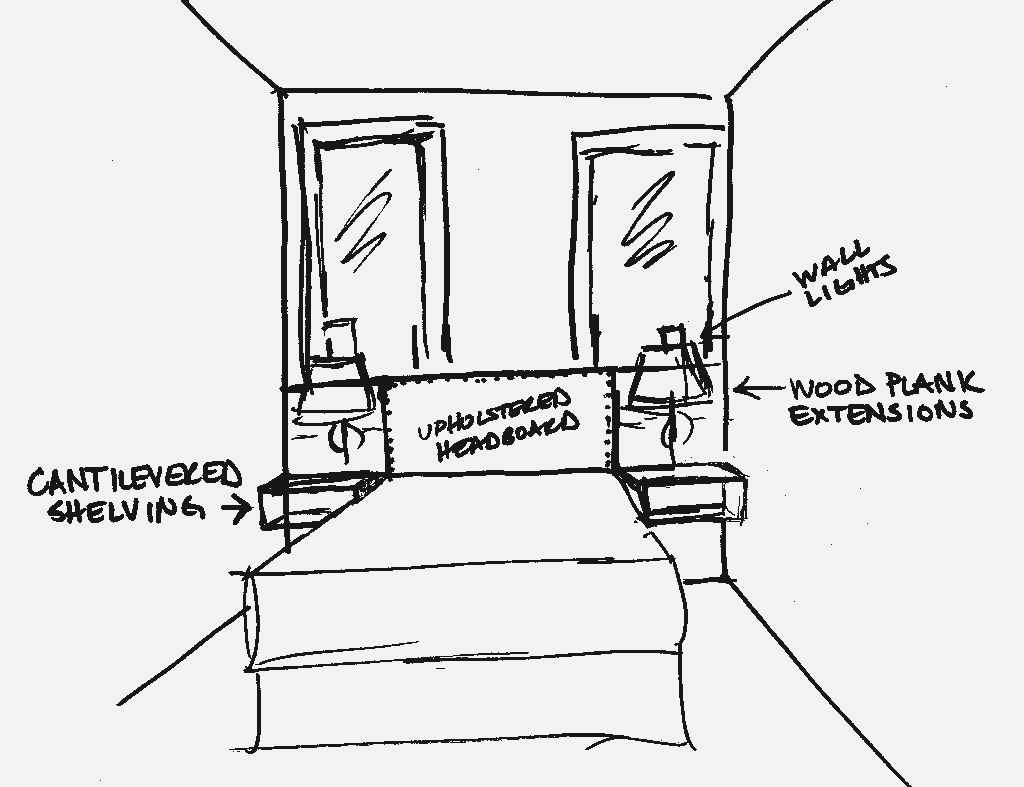

DIY Upholstered Headboard Wall – Part 1 by Andrea Beckman

Every design starts with a vision. This vision is often inspired by a particular piece you love…a chair, a table or piece of artwork. Whatever it may be, it begins to set the tone and direction in which you design; but sometimes certain things such as layout or window placement can hinder that vision. Prior […]

the cover-up by andrea beckman

When I recently moved into my new apartment I absolutely loved everything except for two things…. 1. My extremely short bathroom sink. 2. The brick facade above my fireplace! Now, I’m a huge fan of exposed brick and will take it wherever I can, but this…this is not your beautiful brick. This my friends is […]

DIY – Chevron Pattern Dresser – Kimberly Reuther

Those who know me best are well aware of my ability to envision possibilities in almost any space and are always pleased with the finished product. However, knowing my visionary ability means they are also cognizant of my low tolerance for detail work and executing these visions myself. Therefore, when I conceptualized transforming this drab […]

Guest Post: 5 Things You Won’t Learn From Cable TV by Cary Baumann

A&E and HGTV still haven’t called, nor have their cameras ever appeared at one of the many properties I “flipped” or rehabbed. I’ve been at it longer than these stations have existed: buying foreclosed and distressed properties fixing them up, staging them and selling the property for a profit. It did surprise me that someone […]